Aim.

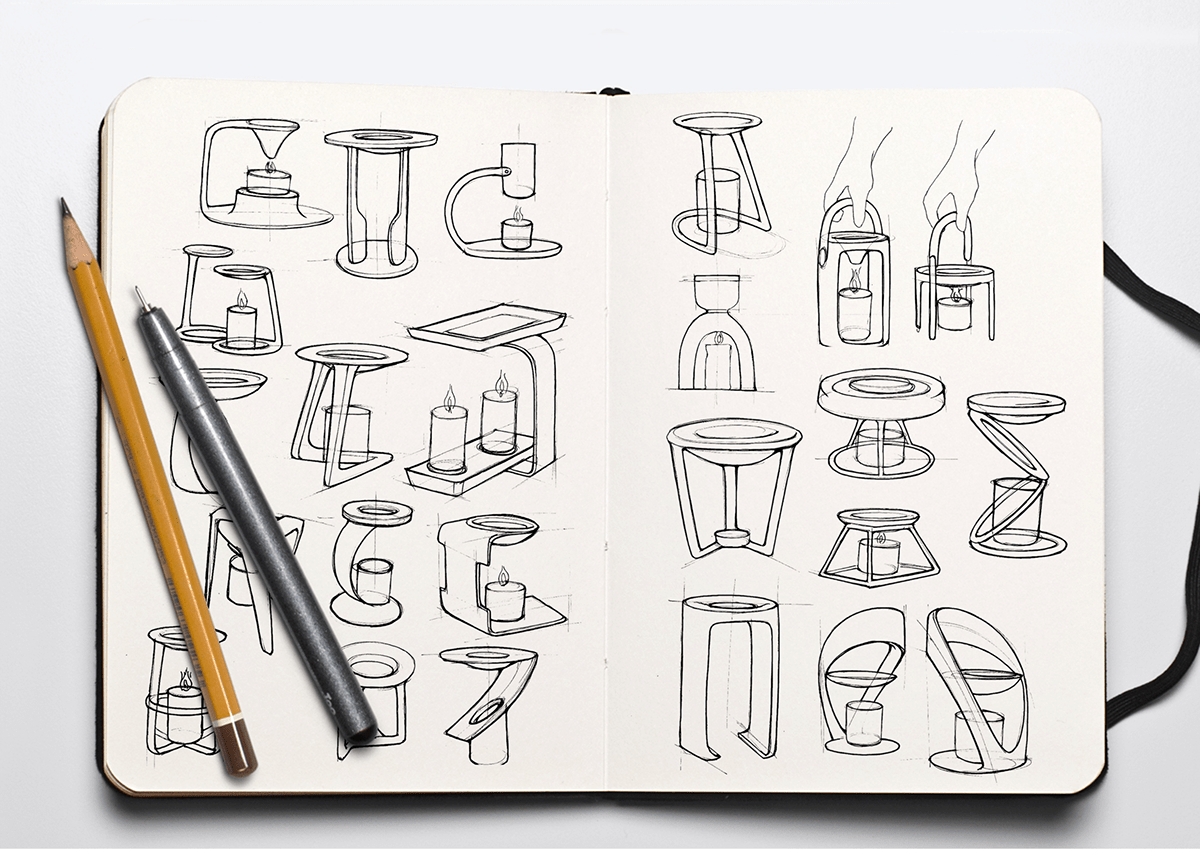

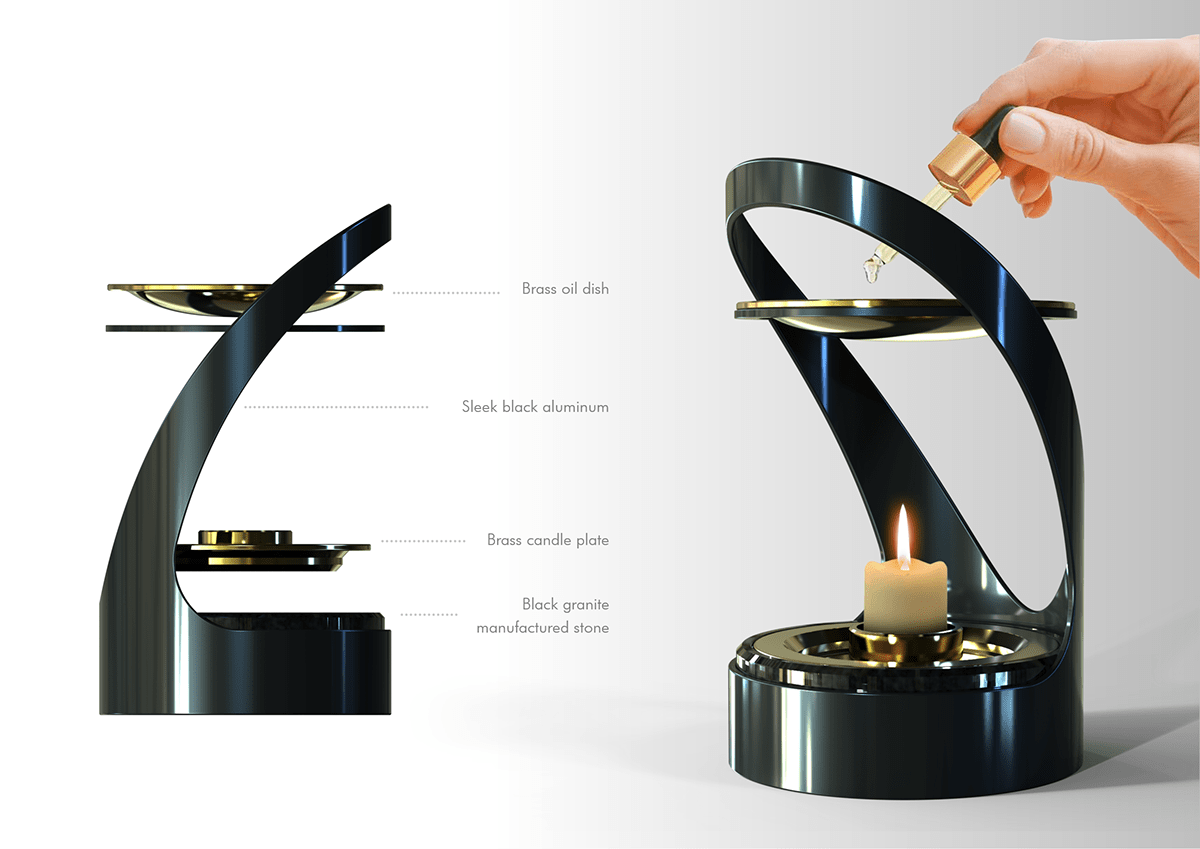

Designing an oil fragrance burner is visually engaging even when not being used and also adopts a sturdy material in order to increase the product durability.

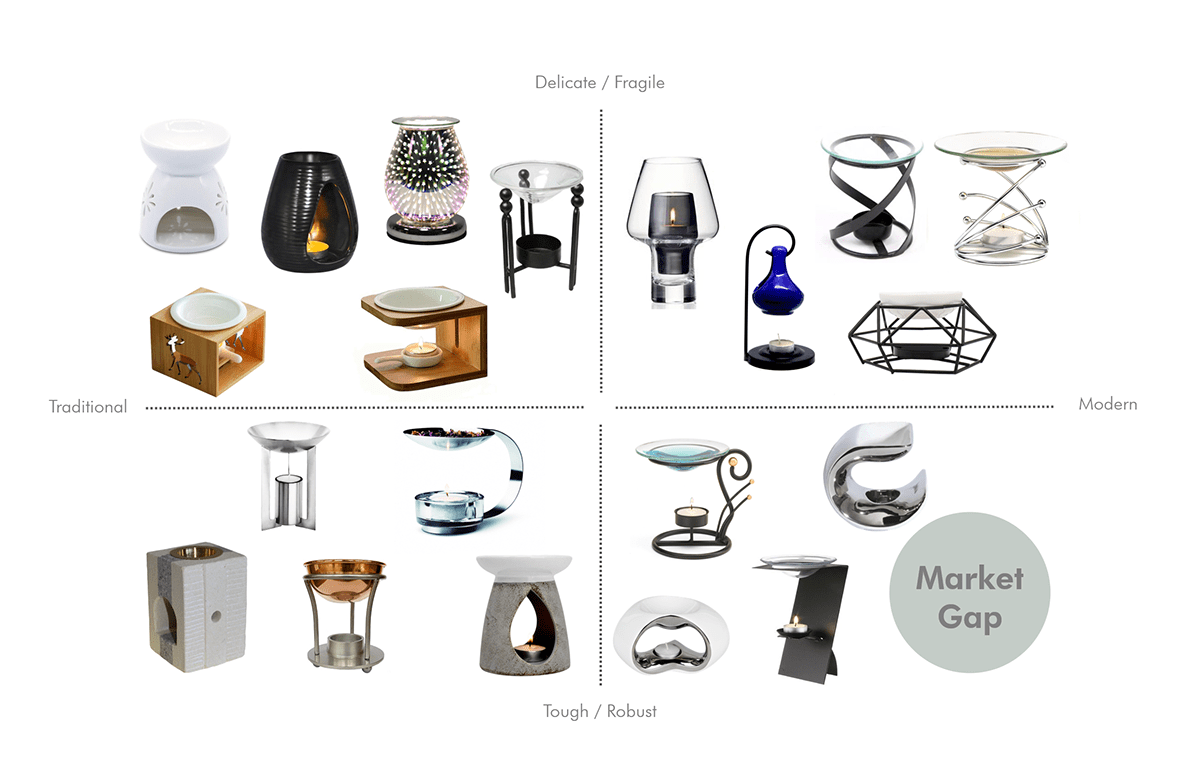

Introduction.

Many existing oil fragrance burners are generally based on ceramic materials, also there are few elements in aesthetics and the unique value of the product. Therefore, the oil burner design should consider the material that must be strong enough to take a few knocks around the house as well as in transit. In addition, it should be designed to be on display even when not being used. In other words it should be visually engaging like an ornament as opposed to say kitchenware which is stored away when not in use.

Upkeep and Cleaning.

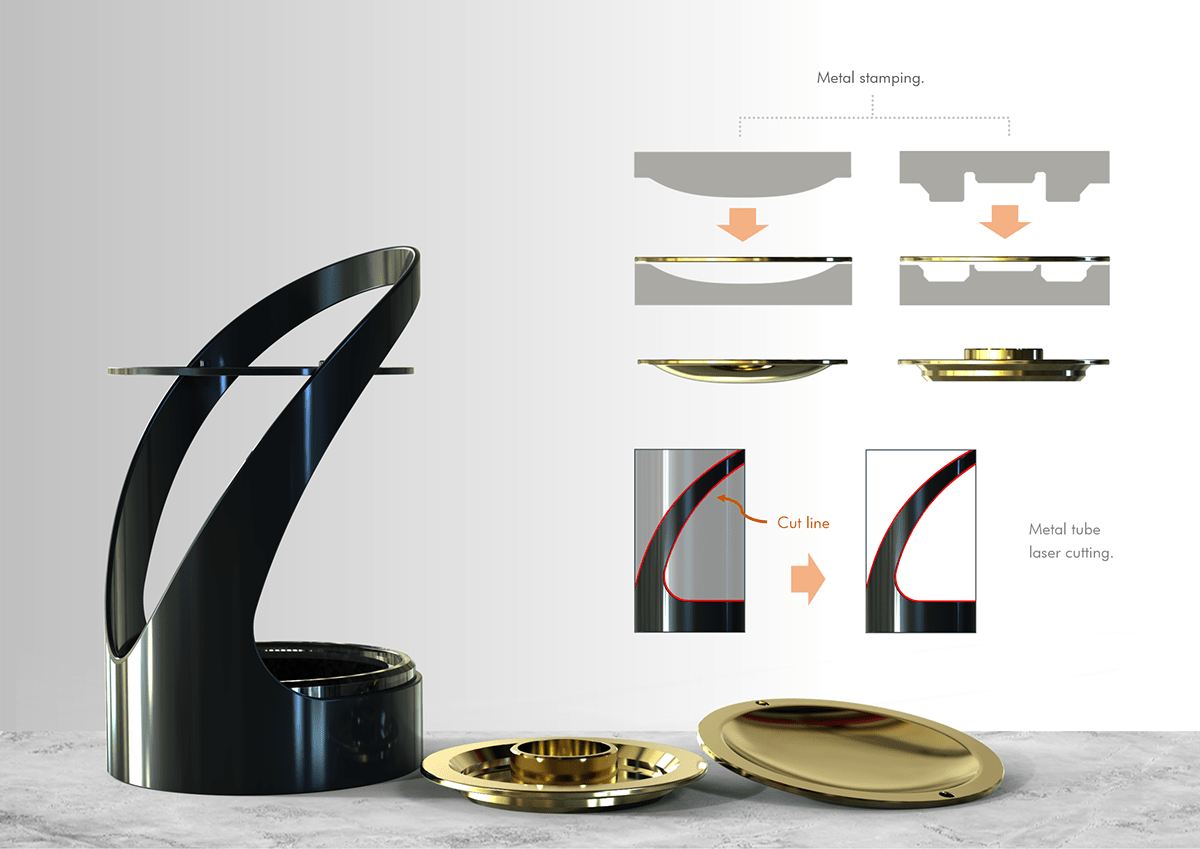

The oil dish and the candle plate are removable, the user can only take out these two parts for cleaning, upkeep, or replacement, without the need to clean the entire product. This design can effectively extend the life of the entire product, and reduce the process and time of cleaning and upkeep.

Design for Manufacture.

Metal Tube Laser Cutting.

Adopting Ø 90 *150mm aluminum pipe with 2mm wall thickness. By rotating and cutting at the same time, it can cut the specific lines and holes on the metal pipe.

Metal Stamping.

This manufacturing technique is used to make the brass oil dish and candle plate.

Adopting the brass flat sheet and put into a stamping press to form the brass sheet into the desired shape.