For this project, I was given the task of designing a 30,000 sf. bicycle factory headquarters for a new company, Re_Cycle Bicycle Works, containing manufacturing, retail, and office space, and sited near downtown Philadelphia. Re_Cycle Bicycle Works, noticing the potential of urban living, and the rising trend to live in the city, manufactures folding bicycles using recycled aluminum. These bicycles fold up into a compact size, making them the perfect companion for city commuters, allowing them to be carried with them on a bus or into a building. This eliminates the likelihood of theft and makes bicycling more convenient, giving city-dwellers a great way to travel and helping to lessen dependence on cars. I see them as doing a great service to the city of Philadelphia. Furthermore, the headquarters will be located off of the Reading Viaduct, an old elevated railway that will soon be renovated into a linear park/bicycle route through the city. Thus, the Viaduct will become a place of energetic, bicycle motion, the kind of energy that Re_Cycle Bicycle Works is helping to foster in Philadelphia, and from which it will survive off of. Re_Cycle Bicylce Works’s use of a recycled material in their manufacturing process, the service they are doing for Philadelphia, their local roots, and their location next to the Viaduct inspired me when I designed the headquarters.

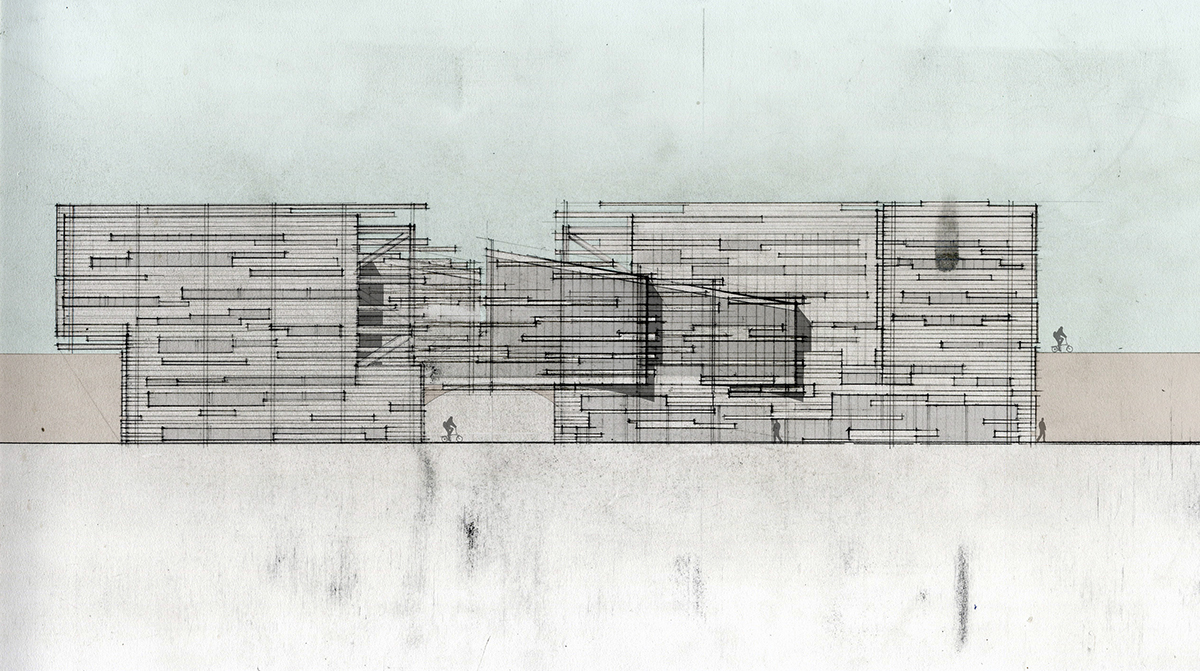

These drawings above were done early in my process to help capture my ideas both programmatically and emotionally. I was exploring how to expose the service that Re_Cycle Bicycle Works does for the city to people outside the company. The heart of Re_Cycle Bicycle Works, where this service is most potent, is the manufacturing floor, where the skilled welders, painters, and mechanics build the bicycles. Thus, I found that giving hierarchy to the manufacturing floor and allowing other spaces to connect with it would be important. Also, as a local Philadelphia company, it would be part of Re_Cycle Bicycle Works’ identity to show its local roots, and I found that having its appearance influenced by Philadelphia vernacular would show that.

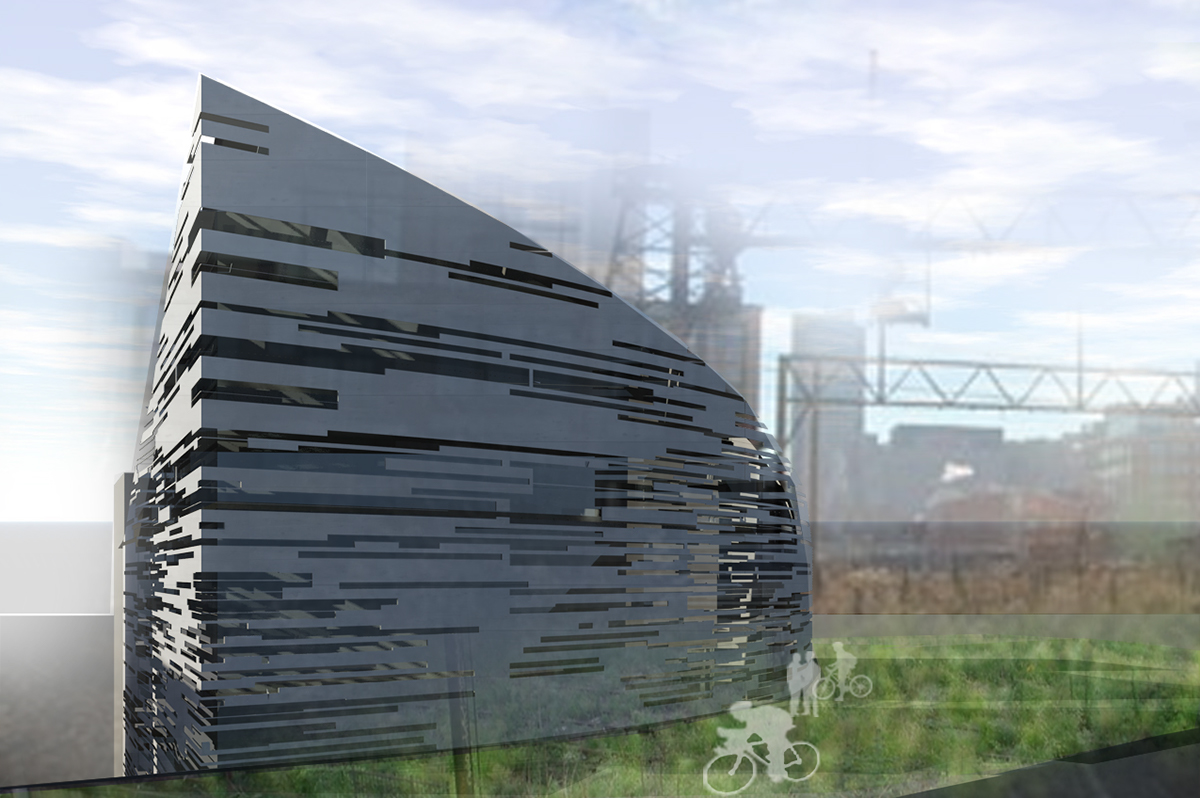

Although vernacular influence is where the aesthetic appearance began, the above images depict what the design was moving towards. Influenced by Philadelphia’s history of brickwork, I continued to explore the use of modular units. The modern material that I settled upon is HDPE planks, because they are made from recycled milk carton plastic, just like how Re_Cycle Bicycle Works uses recycled aluminum in their bicycle frames. They can be arranged in a pattern that encourages the motion and excitement along the Reading Viaduct, and their modular units are a remote link attributing Philadelphia’s vernacular past. The planks look similar to wood, and can be attached to a substructure behind. Controlling the placement of the planks, regarding their sparseness and density, affects how much daylight and glare enters certain parts of the building. Additionally, there was the possibility for developing the façade into a rain screen using this material, an energy efficient advantage.

The images above were done after I had decided on the façade system. Having created a façade system rich with the energy of urban bicyclists, I worked on carrying the shifting look of the façade over into plan, allowing programmatic masses to shear across each other. In turn, the work I did in plan re-informed the project in elevation, helping me to refine the facades to be read as different parts being sheared across each other. Below, as the project concluded, I refined the concepts I had been working with throughout the project.

11th Street elevation

Reading Viaduct elevation

sub-ground plan

As I mentioned before, hierarchy is given to the manufacturing floor, it being placed slightly below the level of the Viaduct, and having retail spaces and office spaces look into it, developing a sense of connection between the different disciplines of the company, and allowing shoppers to see the manufacturing first hand, and developing respect for the workers.

section c-c

interior view of the second floor, facing north

The manufacturing floor and the other program spaces use different envelopes. The manufacturing floor yields the most natural daylight, with a more sparse arrangement of HDPE planks in front of a triple glazed curtain wall, roofed with a vegetated roof, sloped to the Viaduct. The rest of the building uses a tighter arrangement of HDPE planks, in front of an aluminum stud wall with strategically placed horizontal windows, roofed with a typical built-up insulation and membrane roof. These differences help to separate the manufacturing floor from the rest of the building, giving it hierarchy, and reinforcing the shearing of building masses. Furthermore, by limiting the use of a curtain wall to only certain parts of the building, I can increase the thermal efficiency of the building; and, sloping the roof of the manufacturing space decreases its volume of conditioned space, again, contributing to thermal efficiency.

section a-a

detail A

detail B

detail C

viaduct wall section (west wall of section b-b)

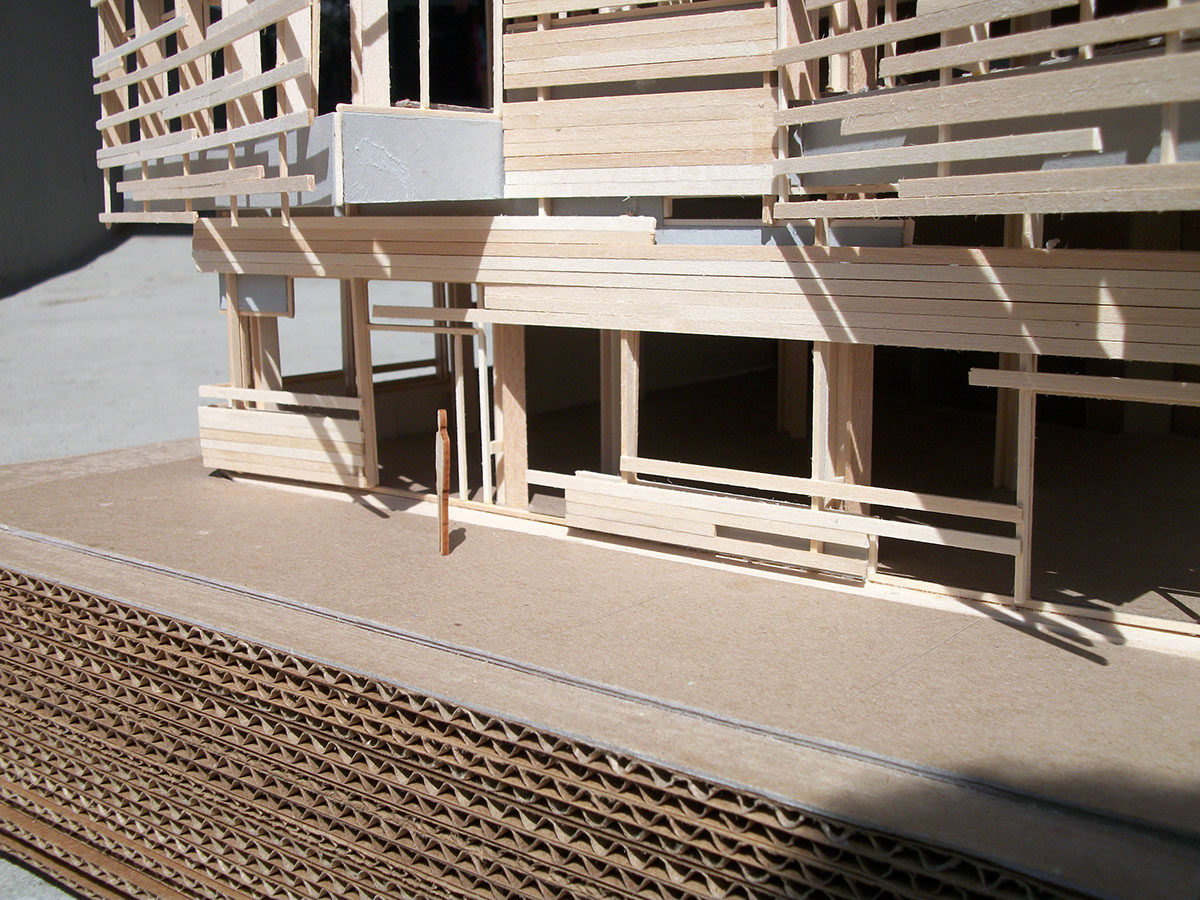

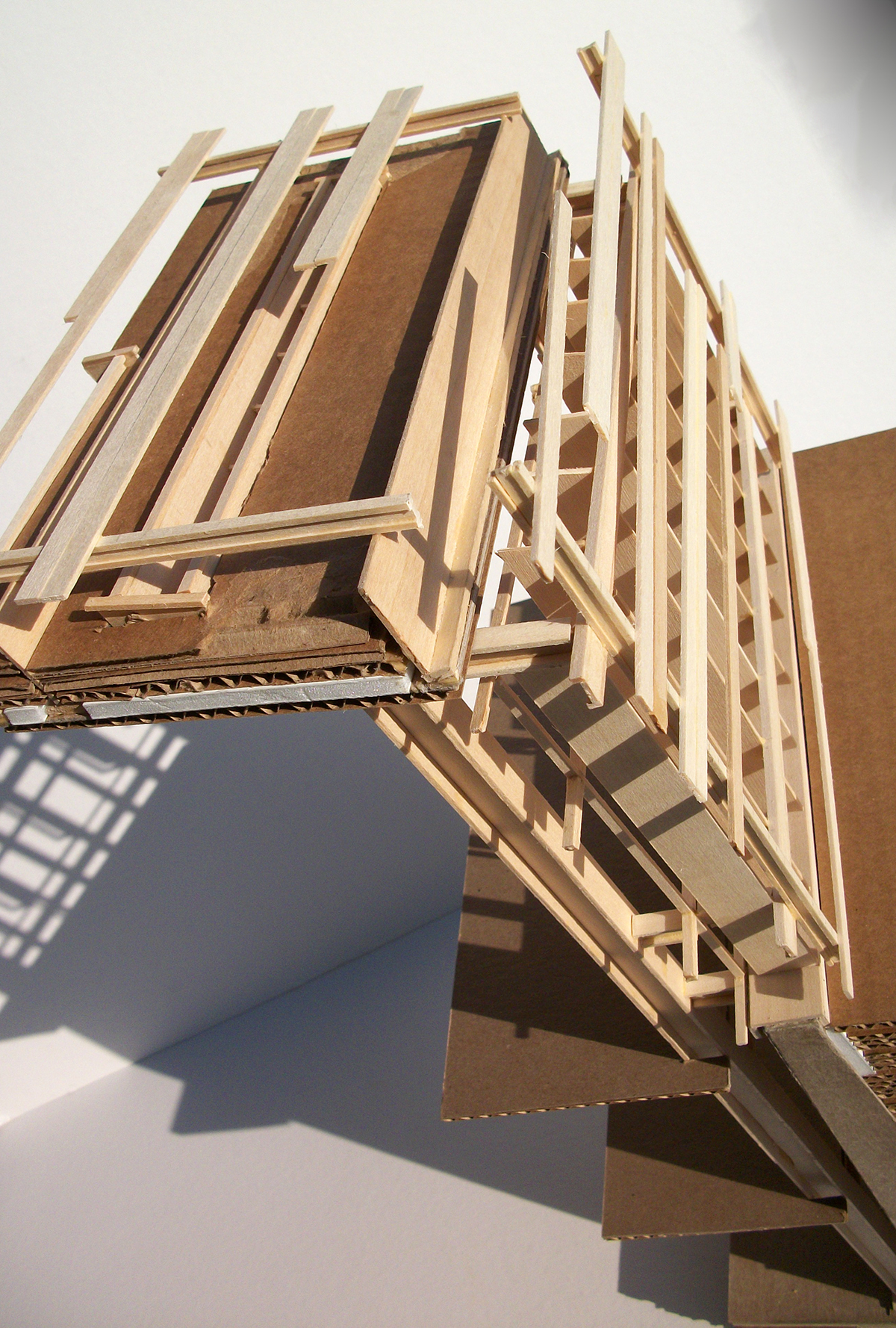

1/2"=1'0" wall section model

1/4"=1'0" partial model (northern portion of building)

view with the vegetated roof removed, looking into the manufacturing floor

west wall, along the Reading Viaduct